Der Maßstab in der Dosierung flüssiger bis pastöser Medien

Die 1987 gegründete AMTEC Kistler GmbH ist führender Hersteller von Maschinen und Automatisierungslösungen zum Dosieren und Versprühen dünnflüssiger bis pastöser Medien in der Fertigung automobiler Blechteile. Zu unseren Kunden zählen führende deutsche und internationale Automobilhersteller sowie Zulieferer. Insbesondere bei Platinen-Beschichtungssystemen vor dem Tiefziehprozess im Automobilpresswerk (sogenannte Spot-Beölungsmaschinen) sind wir Technologieführer. Das Triboflex-System setzt hier einen neuen Industriestandard.

Produkte

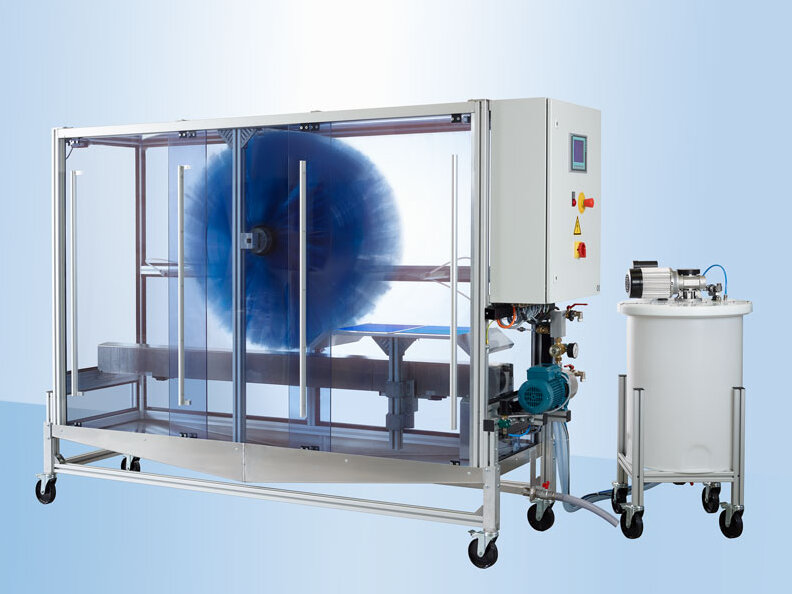

Amtec Triboflex®-Technologie

Prozesssicherheit & Flexibilität bei der Platinen-BeölungAmtec-Platinen-Beschichtungssysteme sind die wirtschaftlichste Lösung zum sektionalen oder vollflächigen Beschichten von Stahl-, Aluminium- und Edelstahlplatinen mit Umform-Schmierstoffen. Die Sprühbeschichtung garantiert besonders dünne und gleichmäßige Schichtdicken.

Netzwerk

DUMA-BANDZINK GmbH

Die DUMA-BANDZINK GmbH ist ein international tätiges Maschinenbauunternehmen mit Sitz in Mönchengladbach, Deutschland. Das Unternehmen entwickelt, konstruiert, fertigt, montiert und modernisiert Maschinen und Anlagen in den Bereichen Bandveredelung und Kaltwalzwerke der Stahlindustrie. Weitere Geschäftsfelder sind der technische Service sowie das Ersatzteilgeschäft für vorgenannte Anlagen. Weltweit sind die Produkte der DUMA-BANDZINK GmbH vor allem bei allen Verzinkungsprozessen im Einsatz, spezielle Anwendung finden sie bei der Herstellung hochwertiger Bleche, wie sie beispielsweise im Automobilbau gefordert werden.

Zudem deckt die DUMA-BANDZINK sämtliche Bereiche des elektrostatischen Einölens von Bändern und Platinen ab – von der einfachen, kostengünstigen Standardmaschine zum Auftrag von Rostschutzölen über speziell entwickelte Maschinen zum Auftrag verschiedener Spezialölsorten inklusive Drylube bis hin zu Spezialmaschinen zur Mikro-Einölung in der Aluminiumindustrie.

Zum 1. Juli 2018 hat die DUMA-BANDZINK die Gesellschaftsanteile der AMTEC Kistler GmbH vollständig übernommen. Durch diese Akquisition und im Verbund mit der AMTEC Kistler wird die DUMA-BANDZINK zum Komplettanbieter im Bereich der Beölung von Stahl und Aluminium von der Erzeugungsstufe im Walzwerk und Bandbehandlung, als auch in der Weiterverarbeitung im Karosserie-Presswerk.

Weitere Informationen zum Unternehmen und den Produkten finden Sie auf unserer Webseite

Kontakt

Amtec Kistler GmbH

Amtec Kistler GmbH

Gewerbering 11

86931 Prittriching

Prittriching, Deutschland

Telefon: +49 8206 9612-0

Fax: +49 8206 9612-30

Mail: info(at)amteckistler.de

Web: www.amteckistler.de

Daniel Plätzer

Amtec Kistler GmbH

Managing Director

Gewerbering 11

86931 Prittriching

Germany

Telefon

: +49 8206 9612-0

Geschäftsadresse

Amtec Kistler GmbH

Gewerbering 11

86931 Prittriching

Deutschland

Telefon: +49-(0)8206-9612-0

Fax +49-(0)8206-9612-30

Email: info@amteckistler.de